Contact Us For Pricing:

(954) 306-3180 | info@winecellarinternational.com

Dual-Air Quiet Wine Cellar Cooler Series

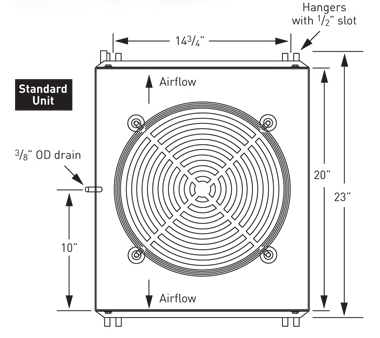

The DUal-Air Quiet (DQ) Wine Cellar Cooling Systems are designed to provide refrigerated air to 55-65 °F. DQ evaporators return air at the bottom and supply two-way air discharge 10-12 feet in both directions at a medium velocity airflow. This promotes fantastic circulation in long and narrow display cases.

These units are the perfect solution for large wine cabinets and walk-in wine cellars. DQ evaporators are available in standard capacities from 1,800 to 4,600 BTU per hour and are used with a R134a refrigerant.

- Air defrosting coil requires does not require an additional heater

- Fan blades engineer for very low-noise

- Staggered high performance coils with copper tubing expanded mechanically into aluminum fins

- Housing constructed with insulated rust-proof aluminum

- Permanently lubricated motor fully thermally protected

- Automatic expansion valve(standard) ensures constant coil temperature to promote “Humidity Balance”

- Pump-down solenoid valve(standard) protects compressor in the event of leaks

Condensing Unit Wiring

Field Wiring

L1 115V Line Voltage

N Neutral

SV Solenoid Valve

FM Fan Motor

TP Temperature Probe

Back of Controller Connections

10 Temperature Probe

11 Temperature Probe

4 Neutral

5 115V Line Voltage

2 Jumper from 5

3 Switch Leg to Fan Coil

C NO Internal normally open contact

Fan Coil Wiring

- Keep line sets as short as possible.

- Excessive number of turns will cause refrigerant flow problems. This could cause early compressor failure. Suction line accumulators are recommended. Required if working lower than the normal 55-65° operating range from wine cellar.

- Drain line must always flow downhill to drain or pump.

- The system is controlled by a pump down control system. There is no control wiring between thermostat and condensing unit.

- The line connections at Fan Coil and Condensing Unit may not be the same as the required line sizes.

- Standard line sets should be 50′ or less. Extended runs may require larger line sizes and 3oz oil must be added for every 10′ over 35′.